As Gülsan Alüminyum, we constantly improve our facilities with investments and aim to improve every day in everything we do.

Our production facilities, located on an open area of 15,000 m², have a total closed area of 10,000 m². Our modern production facilities, which are always kept up to date, have a Molding Room, Extrusion Press Line, Horizontal Electrostatic Powder Coating Line, Mechanical Process Line, Quality Control and Material Testing Department, Packaging and Shipment Department.

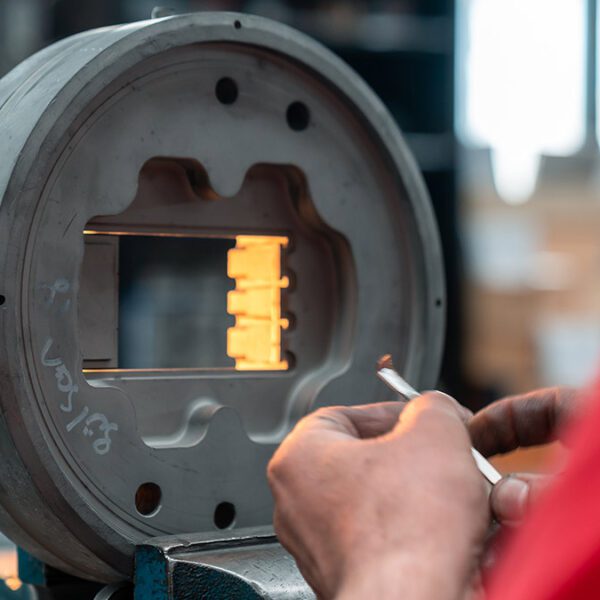

Our molding room; With its 8 years of experience and the strength it draws from its library of more than 2,000 types of molds, it produces molds that will meet the strength, function, perfect surface, size within tolerances, physical properties and quality expectations expected from the profile.

It aims to keep customer satisfaction at the highest level with molds that achieve minimum waste and maximum production by updating its mold technology with the connections it has made at home and abroad.

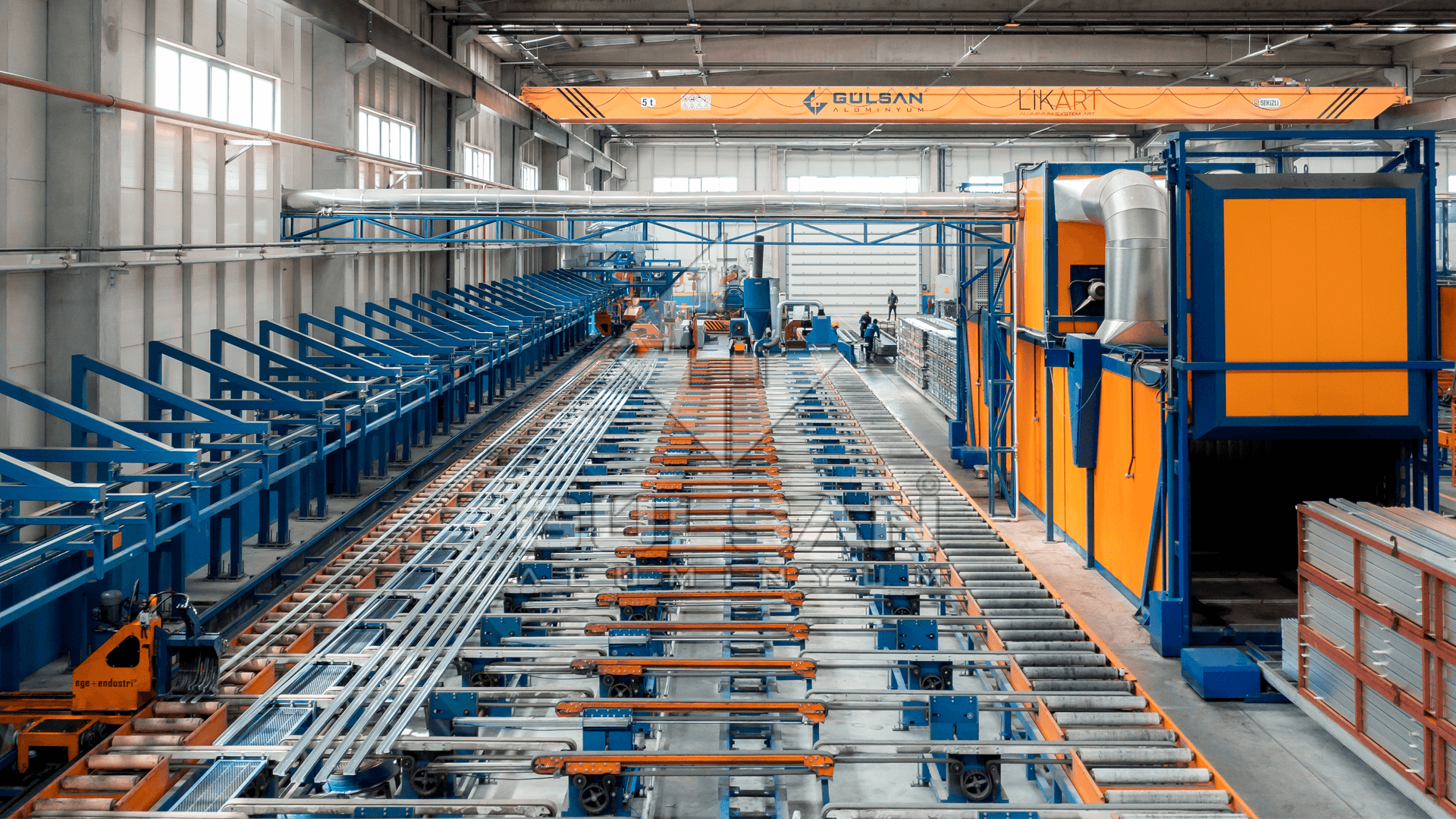

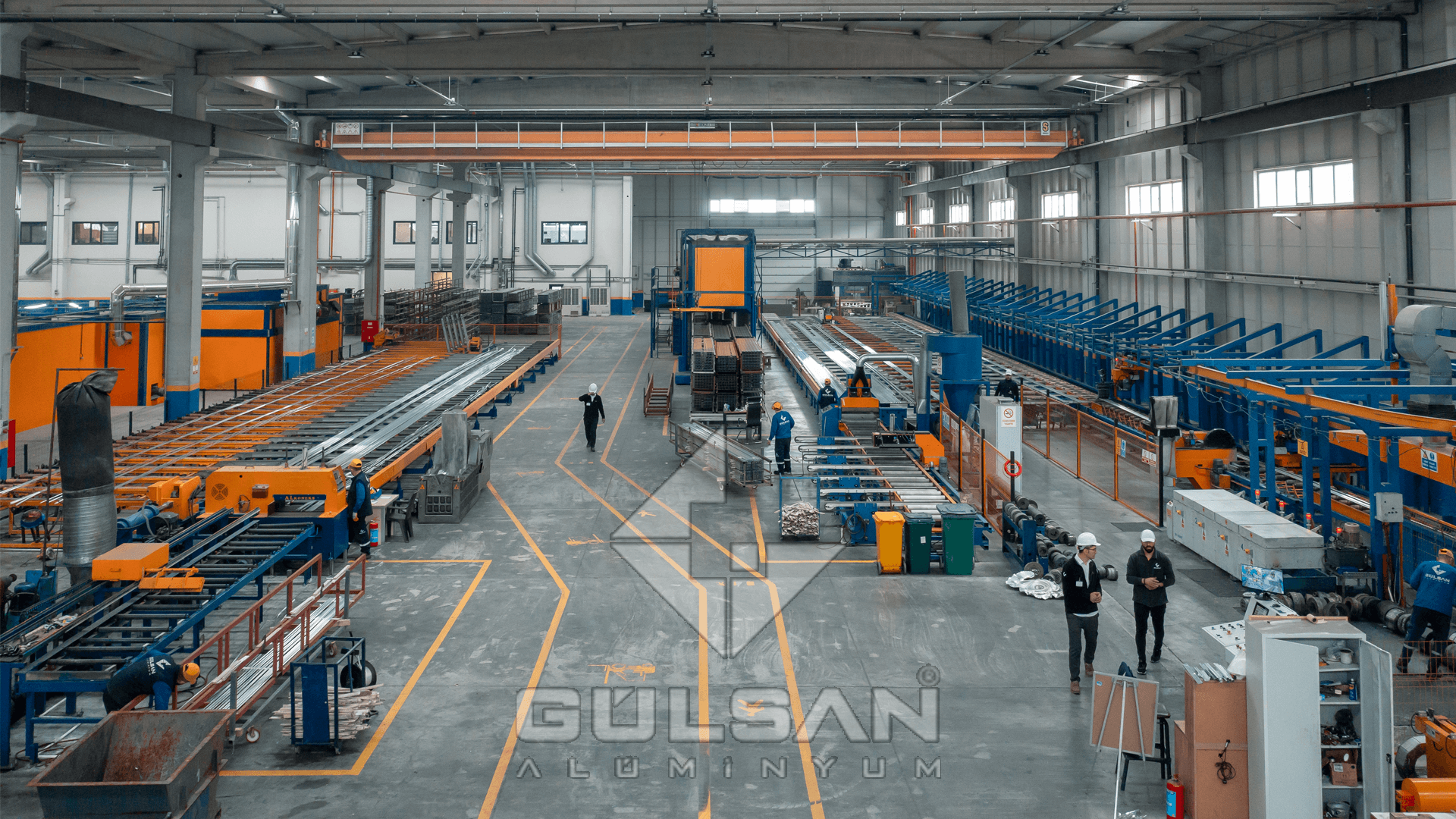

A wide range of aluminum profiles for various sectors and usage purposes are manufactured on our extrusion lines. There are 2 press lines of 5 inch and 6 inch in our extrusion department.

The billets used in our extrusion line are manufactured in 6060, 6061, 6063, 6082 and 6463 series. Our company, which has been manufacturing aluminum profiles since 2013, can easily produce even the most difficult profiles with 10 years of production and 30 years of aluminum experience.

We produce quality with constant controls at every stage of the extrusion process. We are among the most assertive companies in the sector with our annual capacity of 8,500 tons, experience and technology in profile production.

By establishing the Aluminum Electrostatic Powder Coating Facility, GÜLSAN has seized the opportunity to make a sensitive investment in very important issues such as high capacity with new features, energy saving and environmental awareness.

40 Meter Kiln provides energy savings and a monthly dyeing capacity of 400 tons thanks to its 70 meter conveyor tunnel type oven.

With 8 Wagner robotic arms, the facility has the ability to cover 1,000,000 m² of paint annually.

Quality controls of painted products are checked in the laboratory environment by performing weight loss calculations, boiling water test, scratch test, impact test, camber test, cylindrical bending test, gloss measurement and coating thickness measurements.

Powder coated profiles have a decorative appearance. They are also resistant to ultraviolet rays and sudden temperature changes. Painting is carried out with a wide range of colors in different Ral codes according to customer demands.

Gülsan Aluminum Packaging Facility has a wrapping capacity of 3,500 tons/year and a crating capacity of 850 tons/year.

Apart from standard packaging methods, our company offers a wide range of packaging models with Shrink, Foil, Wrapping, Stretch and Strip Drawing machines. With these models, visible surfaces of the profile are protected and ease of installation is provided.

In the packaging methods preferred according to the surface properties of the products, the areas where they will be used and the storage conditions, the profiles produced are carefully packaged by our units after being checked by our Process Control teams, so that all necessary precautions are taken to avoid any problems at the time of delivery.

With the crating methods used in Gülsan Aluminum Packaging Facility, long-distance and short-distance deliveries are ensured without any problems.